Duplex Carton – 300 GSM – Offset Printed

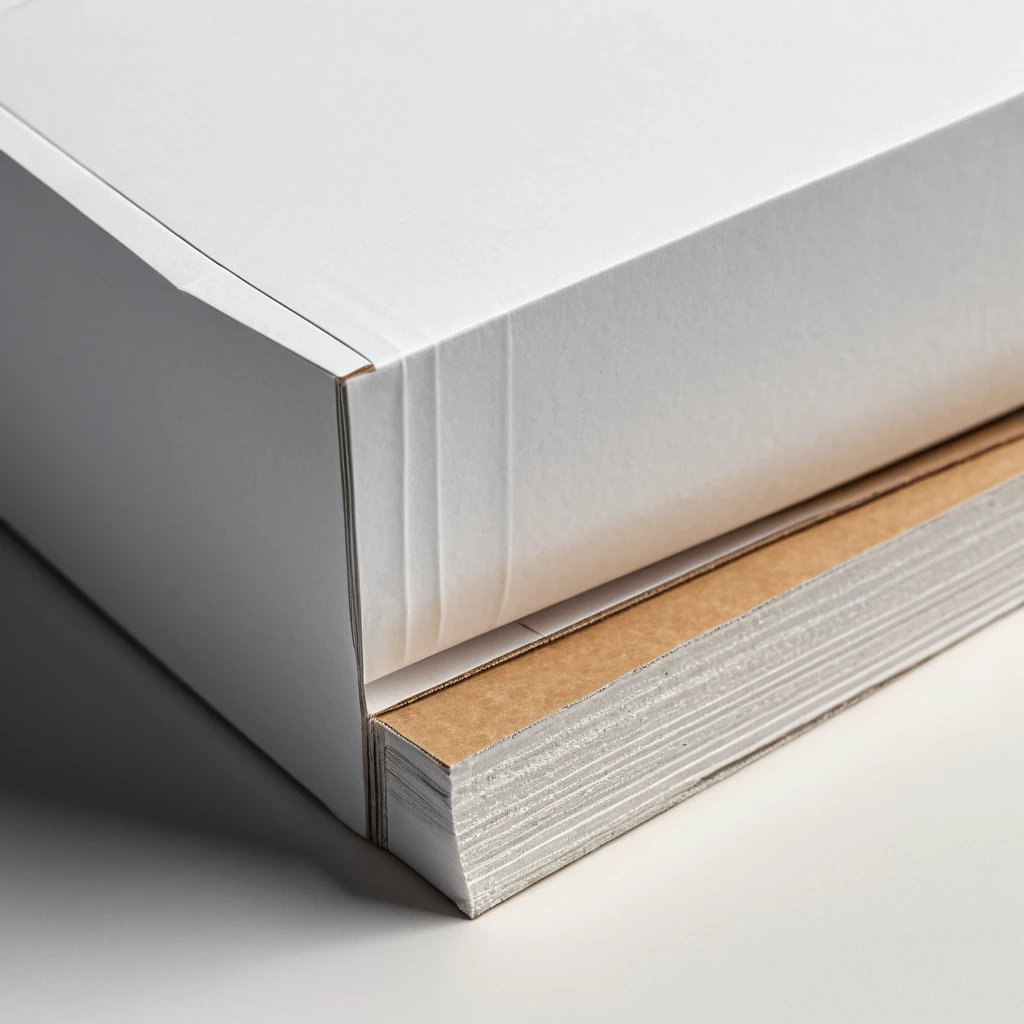

Packaging cartons must balance print quality, structural strength, and cost control. Low-grade boards often warp, crack at folds, or fail to hold color consistency during offset printing, leading to rejection at packing lines and poor shelf appearance. Anaika’s 300 GSM Duplex Cartons are engineered to provide a stable, offset-print-friendly surface with reliable rigidity—ensuring clean print reproduction, accurate die-cutting, and dependable performance during filling, transport, and retail display.

Key Features

300 GSM duplex board offering optimal strength-to-cost balance

Smooth white top layer designed for high-quality offset printing

Consistent board thickness for accurate folding and die-cutting

Resists cracking and edge breakage during carton conversion

Supports sharp color registration and print consistency

Suitable for manual and semi-automatic packing lines

Reliable performance for medium-weight FMCG and pharma packs

Technical Specifications

| Parameter | Details |

|---|---|

| Board Type | Duplex board (white top, grey back) |

| Grammage | 300 GSM |

| Printing Method | Offset printing |

| Surface Finish | Smooth white |

| Die-Cutting | Suitable for precision die-cutting |

| Applications Weight Range | Medium-weight products |

| Shelf Life | 12 months (stored dry) |

Applications

Pharmaceutical secondary packaging

FMCG product cartons

Food and confectionery boxes (non-direct contact)

Personal care and cosmetic packaging

Retail mono cartons

Export-ready folding cartons

Why Choose Anaika?

Low minimum quantities aligned to pilot and repeat orders

Fast turnaround for Mumbai-based packing schedules

Board selection based on real printing and folding behavior

Offset print control for consistent color and registration

Reliable carton quality across repeat production batches