Breakaway Seal Label – Carton Closures

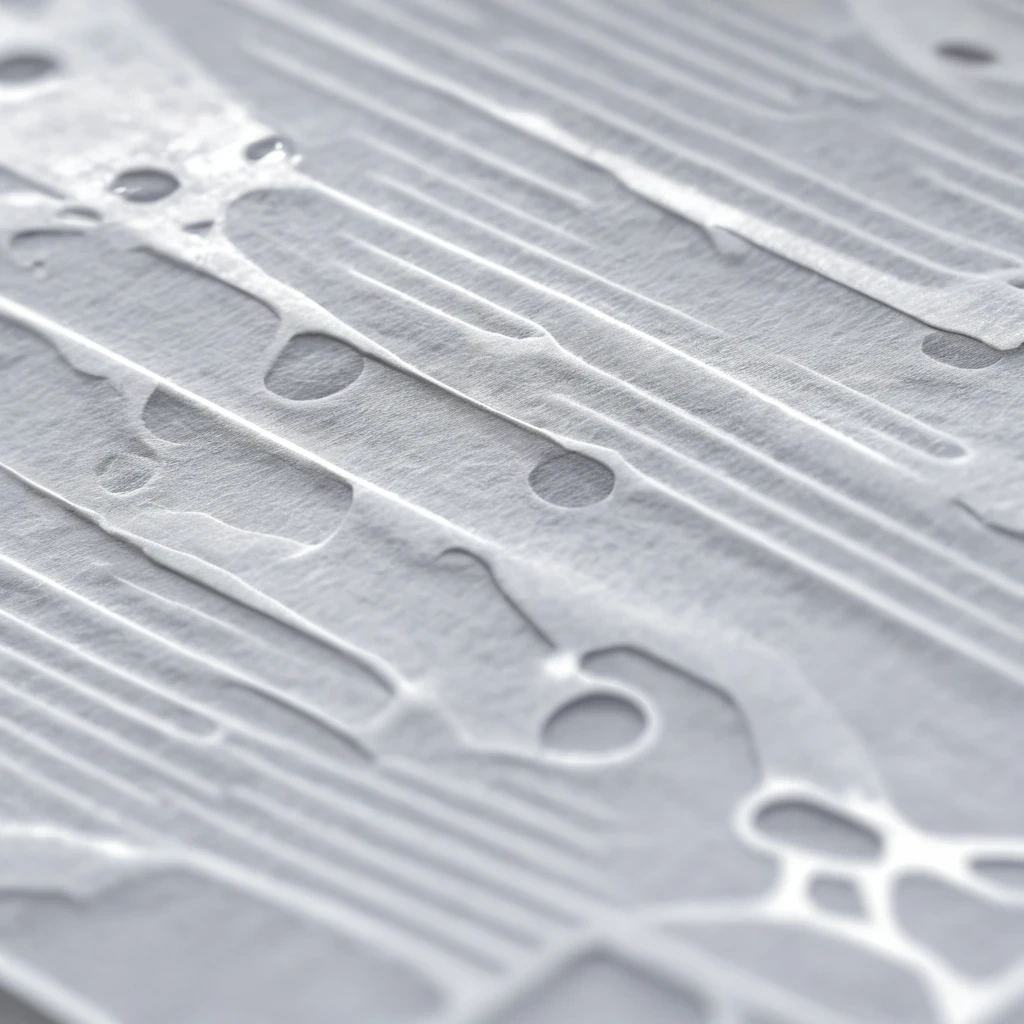

Carton closures in pharma, FMCG, and logistics must show clear evidence of opening. Standard labels can be peeled and reapplied without damage, giving no indication of tampering. Breakaway labels solve this by using engineered tear points that fracture the moment a carton flap is lifted. However, not all breakaway films tear consistently—poor perforation alignment or incorrect adhesive strength can cause partial tearing or premature breakage. Anaika’s Breakaway Seal Labels are designed for predictable fracture behavior, ensuring cartons cannot be opened without visible damage to the seal.

Key Features

-

Engineered breakaway perforations that tear instantly upon flap lifting.

-

Permanent adhesive prevents clean peeling or resealing.

-

Suitable for coated and uncoated carton surfaces.

-

Tear-resistant film except at designed break points.

-

Clean application on manual and automated carton sealing lines.

-

Smudge-resistant coating for branding or printed batch information.

-

Available in multiple break-pattern formats for varying security needs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Synthetic breakaway security film |

| Perforation Type | Micro or macro break-pattern options |

| Adhesive Type | Permanent security-grade acrylic |

| Substrate Compatibility | Pharma cartons, FMCG boxes, shipping cartons |

| Application Mode | Manual or automatic applicators |

| Print Compatibility | Flexo, Digital, Thermal Transfer |

| Thickness | 50–70 microns |

| Security Performance | Label cannot be removed intact |

| Shelf Life | 12–18 months |

Applications

-

Pharmaceutical carton closures

-

FMCG packaging requiring tamper indication

-

E-commerce and logistics carton security

-

Sample and trial medicine kits

-

High-value retail packaging

-

Shipping cartons needing break-on-opening seals

Why Choose Anaika?

-

Breakaway patterns engineered for consistent fracture on every carton type.

-

Adhesive tuned to prevent clean removal while avoiding carton fiber damage.

-

Custom perforation styles for varying security levels and opening forces.

-

Films tested in real packaging-line conditions to avoid premature tearing.

-

High print clarity for branding, QR codes, and compliance information.

-

Expert guidance in selecting film strength and perforation geometry for your workflow.