Vial Labels – High-Tack Adhesive (Glass Vials)

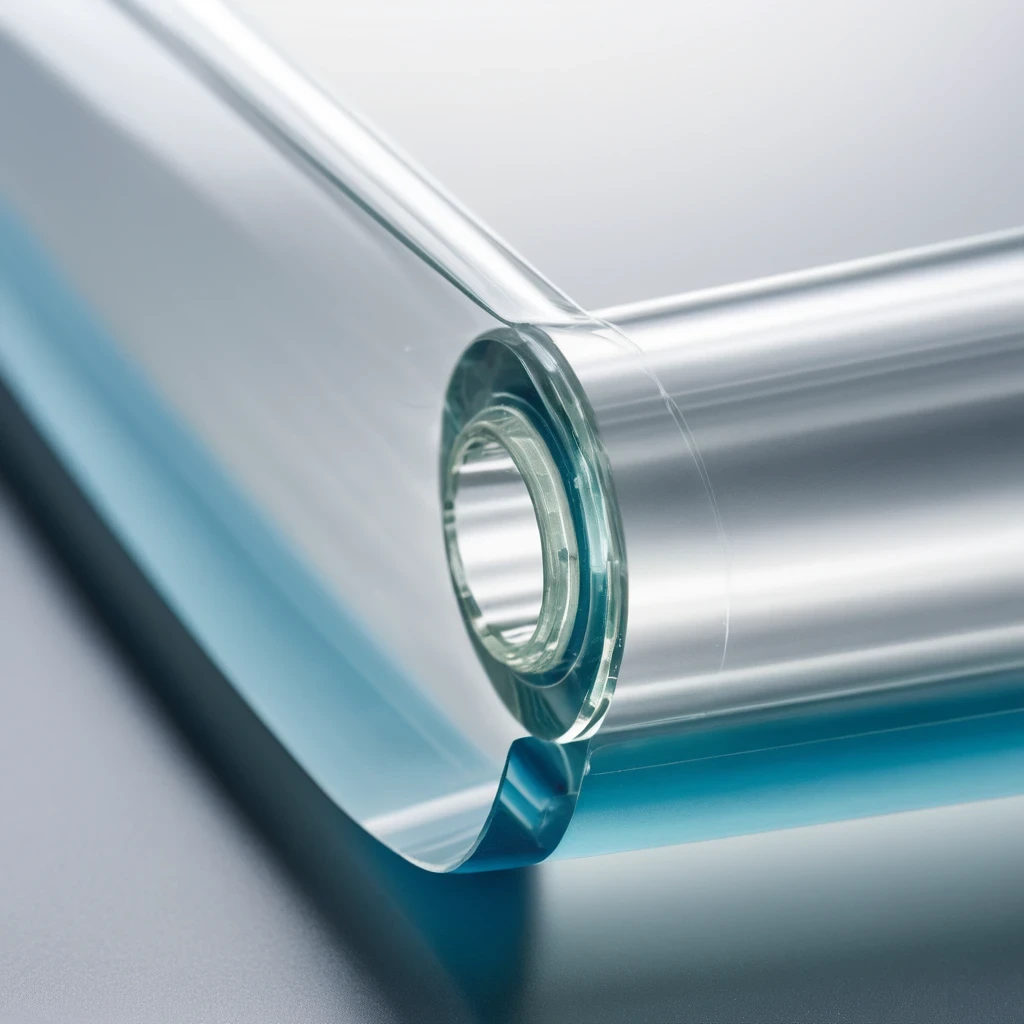

Glass vials used in diagnostic and pharmaceutical workflows often sweat, chill rapidly, and pass through multiple handling stages—causing standard labels to lift, slide, or detach. Regular acrylic adhesives struggle to bond to smooth glass surfaces, especially in cold or moist conditions. Anaika’s High-Tack Vial Labels are engineered specifically for glass substrates, delivering strong, immediate adhesion that remains stable through refrigeration, centrifugation, and repeated manual handling without edge curl or failure.

Key Features

-

High-tack adhesive delivers strong initial grip on smooth, curved glass surfaces.

-

Maintains adhesion on cold, moist, or condensation-prone vials.

-

Flexible film construction prevents lifting at curve edges.

-

Smudge-resistant topcoat ensures data readability during routine handling.

-

Withstands refrigeration, transport vibration, and centrifugation cycles.

-

Compatible with thermal transfer, laser, and digital printing.

- Designed for small-diameter vials commonly used in pathology and pharma labs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Synthetic film (lab-grade) |

| Adhesive Type | High-tack permanent acrylic |

| Substrate Compatibility | Glass vials (smooth, curved surfaces) |

| Temperature Range | –20°C to +70°C |

| Moisture Resistance | Yes – condensation-resistant |

| Print Compatibility | Thermal Transfer, Laser, Digital |

| Total Thickness | 55–70 microns |

| Shelf Life | 12 months (stored at recommended conditions) |

| Core Sizes | 1″ / 3″ |

Applications

Glass serum vials

Pharmaceutical sample identification

Pathology and biochemistry labs

Cold-chain specimen handling

Cryostat and refrigeration workflows

- Research labs needing durable vial labeling

Why Choose Anaika?

Low MOQs tailored to Mumbai labs, pharma units, and research facilities.

Fast delivery for urgent operational replenishment.

Material customization for different glass vial sizes and automated applicators.

Engineering-led label design built around real laboratory challenges.

Consistent, batch-stable adhesive performance for reliable identification.

Compliance-aware manufacturing for diagnostic and pharmaceutical use cases.