Security Seal Label – Perforated

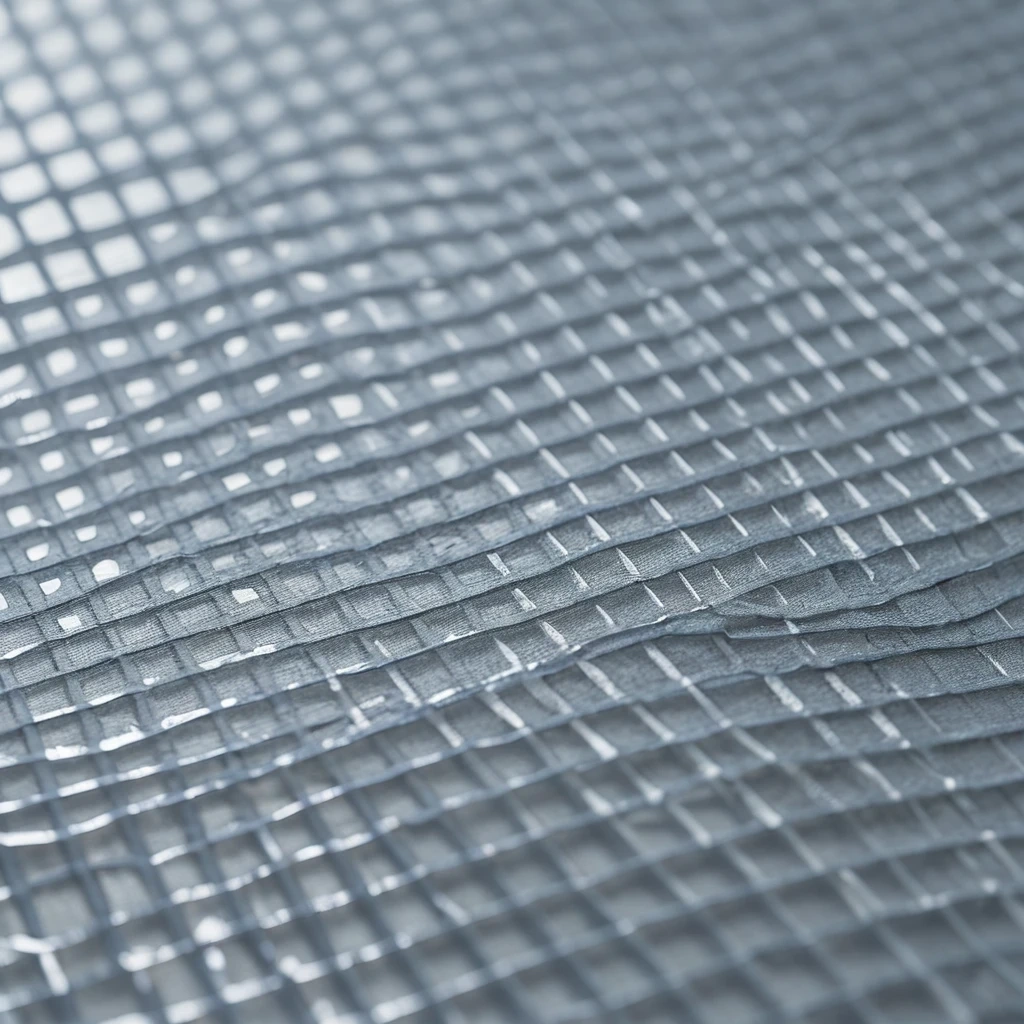

Security seals must break predictably when a carton, bottle, or pouch is opened. Many standard labels either tear unevenly, allowing partial reuse, or fail to tear at all—leading to false security. Poor-quality perforations can also cause premature tearing during transport. Anaika’s Perforated Security Seal Labels use engineered micro-perf patterns that fracture instantly upon opening while remaining stable during handling, ensuring reliable tamper indication and compliance for pharma, FMCG, and logistics applications.

Key Features

Engineered perforation lines designed to tear cleanly upon opening.

Strong adhesive prevents peeling without damage, ensuring true tamper evidence.

Available in fine, medium, and macro perforation formats based on security requirement.

Durable synthetic film resists moisture, scuffing, and transport vibration.

Suitable for cartons, bottle caps, pouches, and multi-panel closures.

Compatible with flexo, digital, and thermal transfer printing.

Tear-resistant outside the engineered break zone to avoid accidental damage.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Synthetic security-grade film |

| Perforation Type | Micro-perf / macro-perf options |

| Adhesive Type | Permanent acrylic security adhesive |

| Substrate Compatibility | Cartons, PET bottles, HDPE bottles, pouches |

| Temperature Range | –5°C to +55°C |

| Moisture Resistance | Yes |

| Print Compatibility | Flexo, Digital, Thermal Transfer |

| Thickness | 50–70 microns |

| Security Performance | Seal breaks predictably at perforation line |

| Shelf Life | 12–18 months |

Applications

Pharmaceutical carton closures

FMCG and cosmetic packaging

Bottle cap security seals

E-commerce and logistics tamper-evident packaging

Retail goods requiring visible tamper indication

Sample kit and medical supply closures

Why Choose Anaika?

Perforation geometry engineered for consistent and predictable tear behavior.

Adhesives tuned to prevent clean peeling or resealing attempts.

Custom perforation patterns and label shapes for varied closure types.

Films tested for durability under transport, moisture, and handling stress.

High print clarity for branding, QR codes, and regulatory text.

Technical guidance to match seal strength with packaging materials and opening force requirements.