Syringe Labels – Removable Adhesive (Hospital Use)

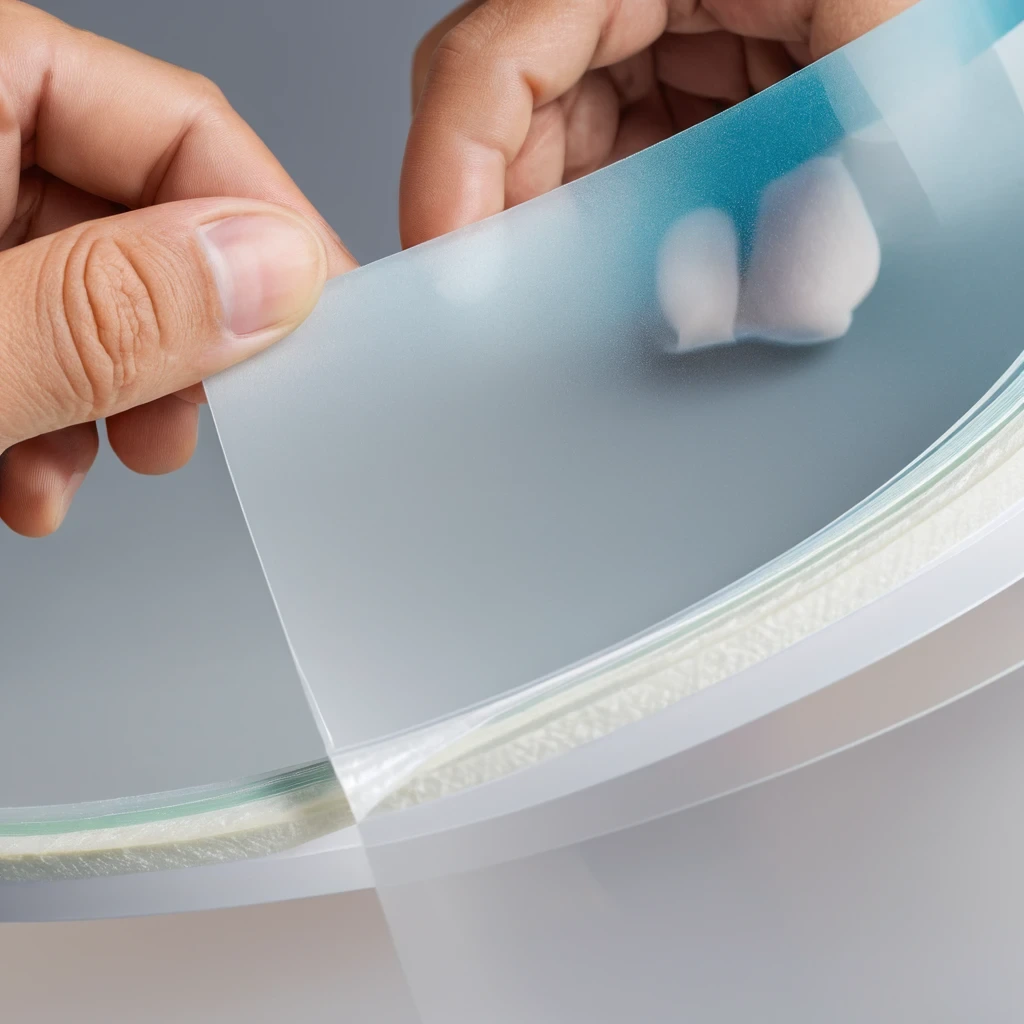

Hospital syringes require temporary identification—labels must stay in place during preparation but come off cleanly without leaving adhesive residue on the barrel. Standard permanent labels compromise this workflow by obscuring measurement markings or leaving residue that affects reuse and calibration. Anaika’s Removable Adhesive Syringe Labels are engineered with a low-tack medical-grade adhesive that holds securely during handling yet peels away cleanly, protecting syringe clarity and ensuring smooth, contamination-free hospital operations.

Key Features

Low-tack medical-grade adhesive that stays secure yet removes cleanly without residue.

Does not obstruct syringe graduations for accurate medication measurement.

Compatible with thermal transfer, digital, and laser-print workflows.

Smooth film that resists smudging from alcohol wipes and routine cleaning.

Flexible construction ensures clean wrap-around without curling.

Designed for quick application and easy removal during fast-paced hospital use.

Suitable for color coding, patient ID, timing labels, or medication prep notes.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Synthetic removable film |

| Adhesive Type | Low-tack removable acrylic |

| Substrate Compatibility | Plastic syringe barrels |

| Temperature Range | 0°C to +55°C |

| Chemical Resistance | Alcohol wipes and mild disinfectants |

| Print Compatibility | Thermal Transfer, Laser, Digital |

| Thickness | 45–60 microns |

| Removal | Clean-peel, no residue |

| Shelf Life | 12 months |

Applications

Hospital syringe preparation

Medication identification and timing labels

Anaesthesia and critical care workflows

Pharmacy compounding units

Vaccination camps and rapid administration environments

Situations requiring clean label removal after use

Why Choose Anaika?

Removable adhesives engineered specifically for medical environments—secure during use, clean on removal.

Films tested for clarity, peelability, and non-residue performance.

Custom label sizes for different syringe capacities and workflows.

Reliable print performance for text, barcodes, and color indicators.

Batch consistency ensures predictable tack and removal every time.

Technical support for selecting ideal film thickness and adhesive strength based on use-case.