Tamper-Proof Warranty Seal – Pharma Kits

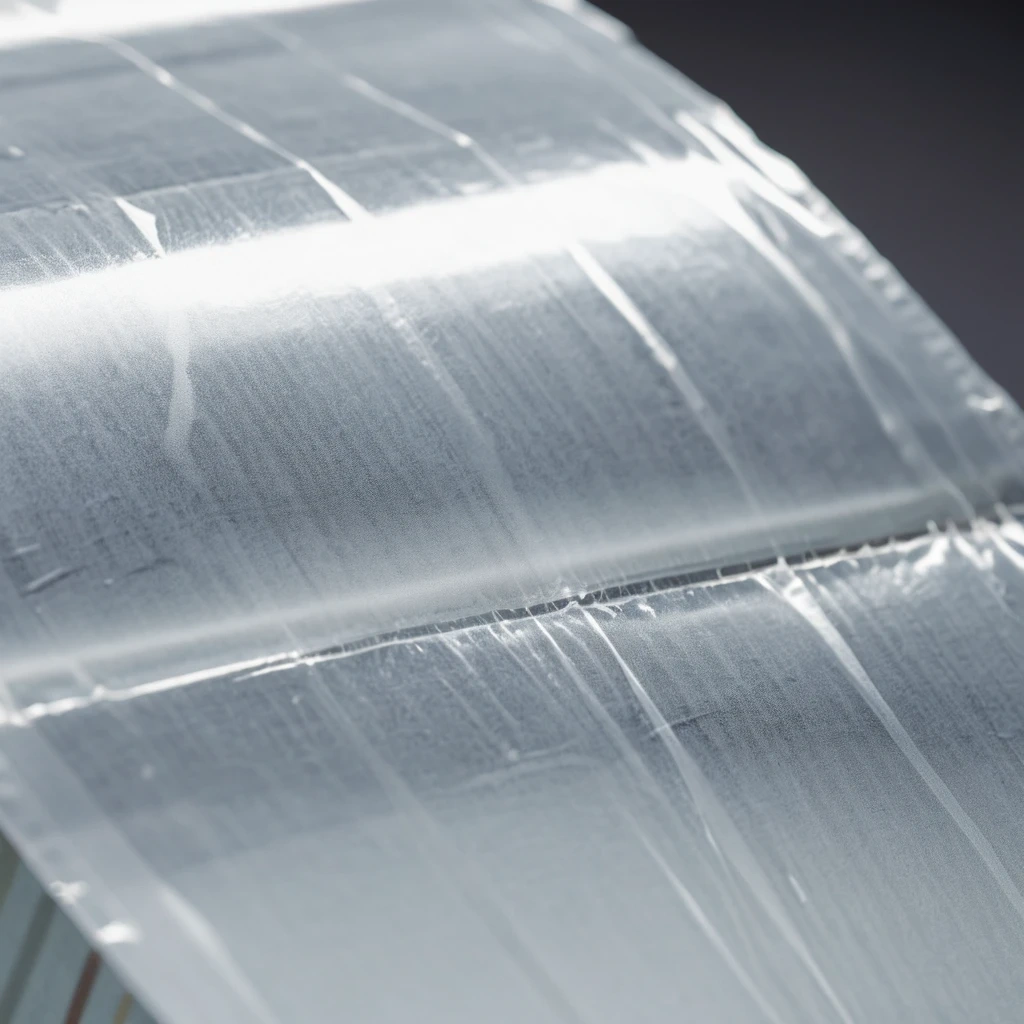

Pharma kits—whether diagnostic kits, sampling kits, device starter kits, or medication bundles—require seals that instantly show any attempt to open or tamper with the pack. Standard stickers can be removed cleanly or resealed without visible damage, creating safety, compliance, and traceability risks. Warranty seals must tear, fracture, or delaminate in a predictable way. Anaika offers tamper-proof warranty seal solutions designed for pharma kits, using frangible films and security adhesives that break upon opening while remaining stable during handling and logistics.

Key Features

Frangible film construction tears immediately when the kit is opened.

Security adhesive prevents clean peeling or resealing.

Works on coated and uncoated pharma-grade cartons.

Moisture- and abrasion-resistant to withstand logistics and cold-chain environments.

Available with break patterns, micro-perforations, or partial-release zones.

Optional write-on or print-ready surface for batch, QR, and expiry details.

Suitable for both manual and automated application lines.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Frangible or destructible synthetic film |

| Security Type | Break-on-lift / fracture / partial delamination |

| Adhesive | Security-grade permanent acrylic |

| Kit Compatibility | Diagnostic kits, device kits, sample kits, medication packs |

| Temperature Range | –5°C to +55°C |

| Print Compatibility | Flexo, Digital, Thermal Transfer |

| Moisture Resistance | Yes |

| Thickness | 45–65 microns |

| Shelf Life | 12–18 months |

Applications

Diagnostic test kits

Sample collection kits for pathology and genetics

Patient starter kits and device kits

Medication combo kits and bundled pharma packs

Regulatory-sealed export pharma kits

Kits requiring traceability through QR codes or batch markers

Why Choose Anaika?

Security films engineered for predictable tear or fracture behaviour.

adhesives tuned for pharma cartons to prevent clean lifting.

Custom die-cuts for kit size, flap design, or closure geometry.

Durable materials tested across packing, storage, and transport conditions.

Reliable print surface for compliance text, QR codes, and branding.

Technical support to match seal type with your kit’s regulatory requirements.